By: Isabella Vaccaro

It all began with Lorena Lopez, a UM graduate student pursuing an M.F.A. in Interactive Media, and some leftover materials she had laying around her home. Lopez, a long-time seamstress and costume designer, said after a few days in quarantine during the COVID-19 pandemic, she noticed a dire need for masks around the world and various groups coming together to make them.

“If people are requesting them, and I can make them, there’s no reason for me not to, especially if I have all the materials at home,” said Lopez, who sewed 36 masks the first day before running out of elastic.

Next thing she knew, Lopez connected with an old friend, Cynthia Kirkland, who had started a group called Print the Curve Flat, which manufactures 3-D-printed face shields and donates them to frontline workers. Another organization, Sew the Curve Flat, unites sewers with a common goal to produce as many masks as possible to fulfill the large orders coming from medical personnel and other businesses.

Amidst Lopez’s round-the-clock mask-making, a happy coincidence occurred when her UM professor, Zevensuy Rodriguez, reached out with a desire to help and a slew of 3-D printers from UM’s campus.

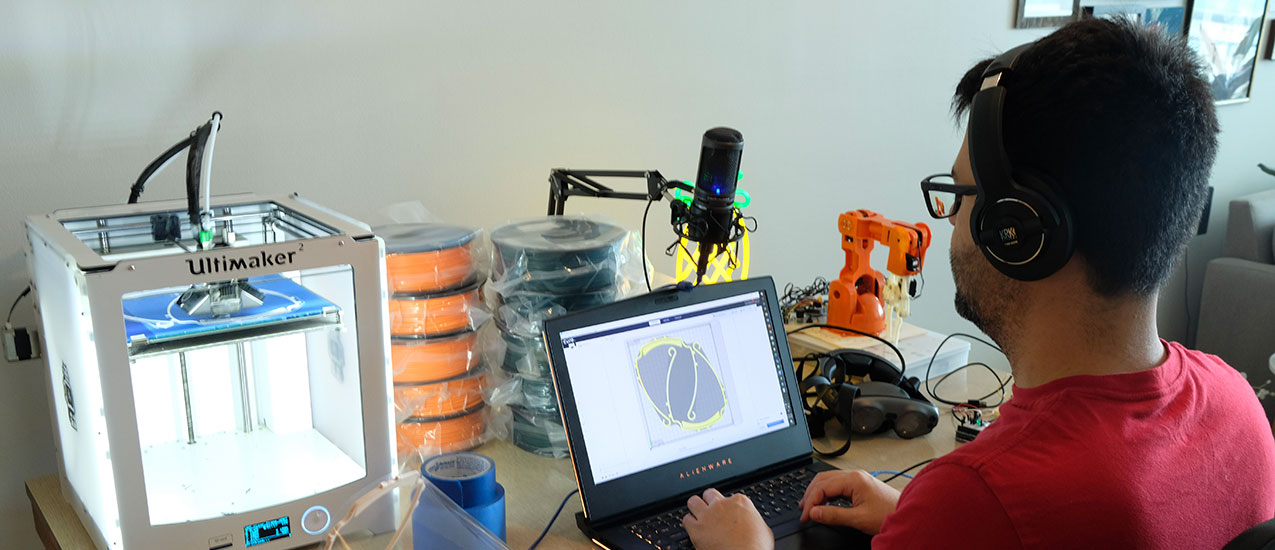

“This is part of my DNA,” said Rodriguez. “I’ve been 3-D printing and making for the better part of ten years, so when this all came about, I initially started reaching out to my colleagues at the university and figuring out what we could do with all the 3-D printers that we have on campus.”

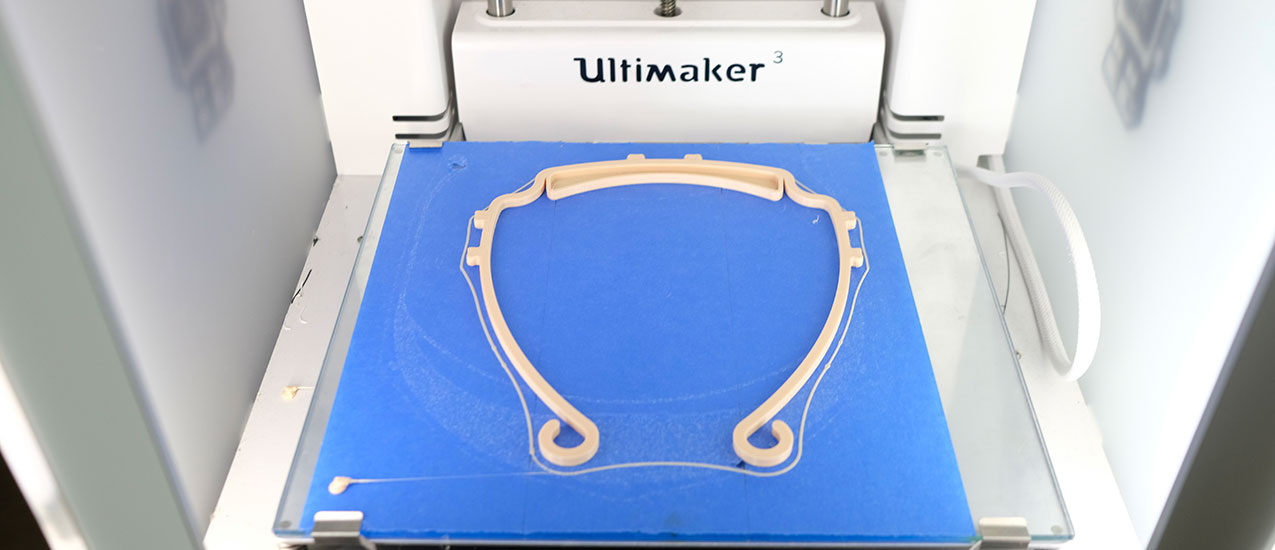

Thus, a beautiful partnership was formed, with Rodriguez printing dozens of plastic headbands a day and dropping them at Lopez’s house where she assembles them with a protective screen and ships them to people around the world.

Lopez added that she actually has a 3-D printer of her own and on top of her daily sewing load, soon began making shields too, which she said increased her and Rodriguez’s production by 25%. She even took on a larger role in Print the Curve Flat shortly after joining.

“I have become the overall coordinator now, so I actually do all the matching on a national level,” said Lopez. “So, we receive all the orders and then I have a list of 300 makers that I have organized based on region and what printers they have available. My role is to actually figure out how to fill these orders in the group based on who’s available.”

Besides the large quantity of orders Lopez is filling in the South Florida area, she has also donated masks and shields to community hospitals and other essential businesses from New York to Las Vegas, Nebraska and Puerto Rico. “I have, at this point, made over 900 masks. I hit 880 and then I stopped counting,” Lopez said.

And although face coverings of any sort are in wide demand around the world, Rodriguez noted he and Lopez are aware they are not producing N-95 masks. He said the shields they’re printing, which have been approved by the National Institutes of Health (NIH), “is a really good first line of defense. Most people wear the shield, then they’re going to wear some sort of N-95 mask, and people are also putting on the fabric type that Lorena is making to further protect the integrity of the N-95 mask, because the N-95 mask is the one that’s in most short supply.”

Lopez and Rodriguez’s operation has protected hundreds of frontline workers during this pandemic, and the two have been able to recruit more volunteers, too. Stephanie Johnson, an undergraduate student studying motion pictures who also works at Richter Library, has been helping to sew masks during the pandemic.

Lopez added that, “whenever we give masks to the facilities, we’re not charging anyone for anything once we donate to them, but they’re also very happy to donate back—it’s a really good love circle of people wanting to help.”

If you’re looking to support the cause, Lopez said they need volunteers to sew masks or print shields. Reach out to her at llopez@miami.edu for more information on how to get involved with Sew the Curve Flat, Print the Curve Flat, and how to donate for the purchase of supplies.